The manufacturing industry is in the midst of its Fourth Industrial Revolution. The digitization of manufacturing, known as Industry 4.0, is changing the way products are produced. The first industrial revolution brought mechanization through water and steam power, the second brought mass production and assembly lines using electricity, and the third brought the adoption of computers and automation. Industry 4.0 is enhancing the automation triggered by the third industrial revolution with smart and autonomous systems that rely on big data and machine learning.

What is Industry 4.0?

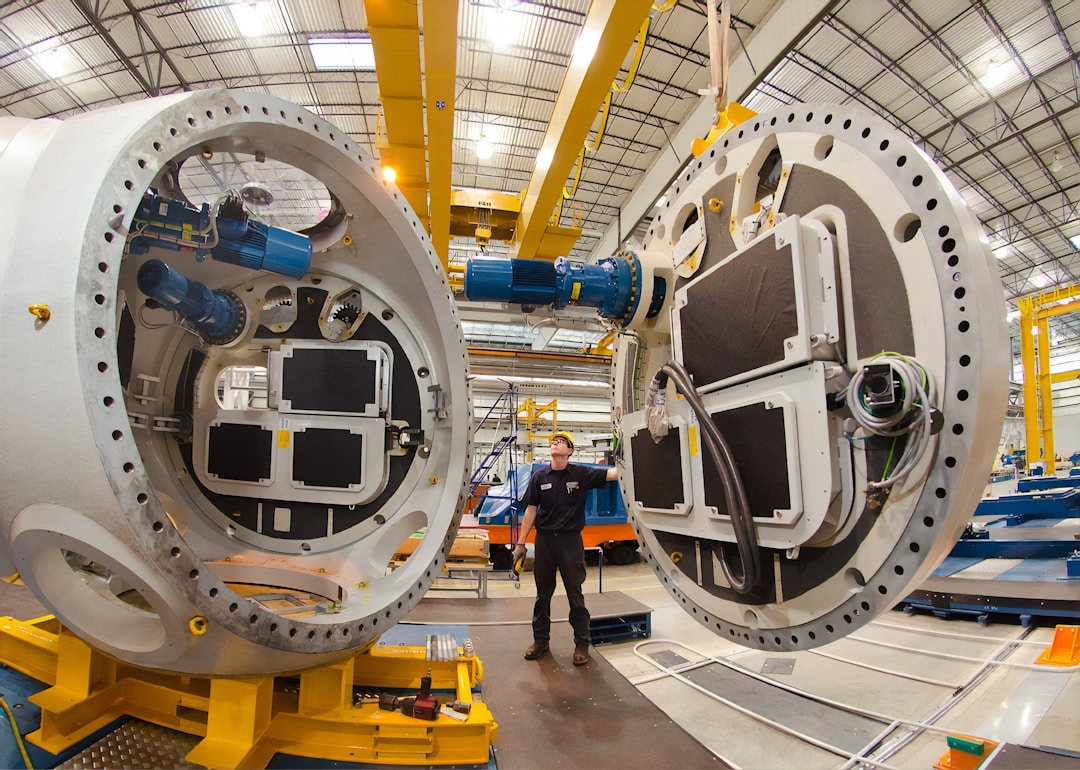

One of the greatest challenges industries are facing is the large amount of big data being generated daily and how to leverage it. Interconnected computers can communicate with each other to make decisions without human intervention. Combining cyber-physical systems, the Internet of Things (IoT), and the Internet of Systems makes smart factories a reality. Artificial Intelligence-powered machines create a smart shop floor that’s efficient, more productive, and less wasteful.

M2M and Internet of Things (IoT) allow for increased automation, improved communication, and monitoring with IoT sensors that allow machines to self-monitor and perform analysis. Smart factories still need reliable high voltage switching equipment for utilities during times of emergency or planned outages.

The Southern States provides customizable mobile transformers and auxiliary trailers that expedite restoration times will provide cost savings to a utility’s network. Their mobile substation transformers can support a range of voltages and are manufactured with stringent specifications. With years of experience in the mobile transformers game, Southern States has the mobile substation and transformer applications that will improve operations, maintain safety, and meet space limitations.

What are the applications of Industry 4.0?

The first step to understanding how Industry 4.0 improves business is to understand the possible applications.

- Identify opportunities: connected machines gather large amounts of big data that provide insights into maintenance, performance, patterns, and other insights that are difficult to see without automation. Being able to identify opportunities allows organizations to efficiently optimize operations.

- Optimize logistics and supply chains: a connected supply chain allows you to proactively adjust to delays and modify manufacturing priorities.

- Autonomous equipment and vehicles: shipping yards can leverage autonomous cranes and trucks to streamline operations.

- Robots: robots can be used in smart factories to safely select and transport products for shipping.

- Additive manufacturing: 3D printing technology has progressed from being used as a prototyping tool to being used in actual production.

- Internet of Things and the cloud: the Internet of Things (IoT) uses cloud-connected sensors that leverage data to optimize equipment and operations.

The Fourth Industrial Revolution combines the Industrial Internet of Things (IIoT) and cyber-physical systems to make all aspects of the supply chain “smart”. Industry 4.0 is built on nine areas of technology: data and artificial intelligence analytics, horizontal and vertical integration, cloud computing, augmented reality, Industrial Internet of Things, additive manufacturing, autonomous robots, simulation, and cybersecurity. Each of these digital innovations bridges the gap between the physical and digital workplace so that smart, autonomous systems can become the norm.

Future Insights provides a brief overview of what you should know about Industry 4.0 and why it’s a good idea for businesses to implement it as part of their digital transformation. There are several applications of Industry 4.0 including collaborative technology, smart products, smart factories, intelligent assets, and empowered people.

Like all new technologies, Industry 4.0 is still evolving. The best thing for organizations adopting new technologies in preparation for a digital transformation is to realize the potential of Industry 4.0. Part of this realization will be understanding how to upskill the current workforce while recruiting new team members with the right skills that align with Industry 4.0.